3D OM

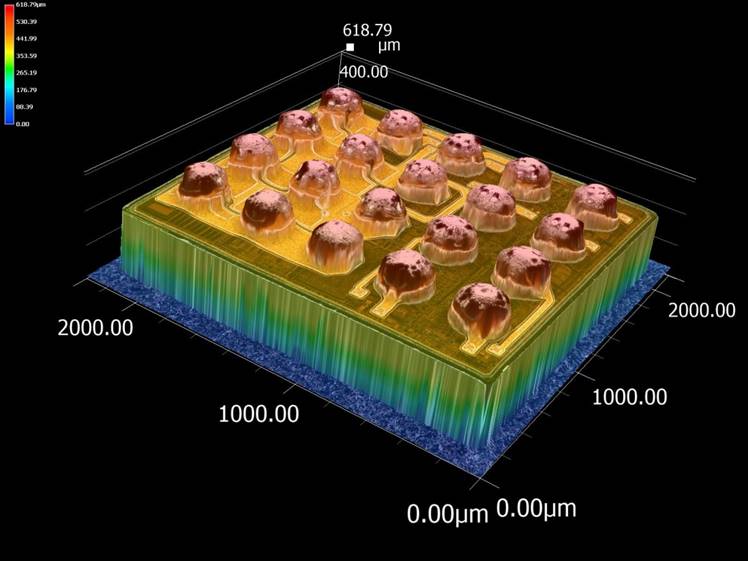

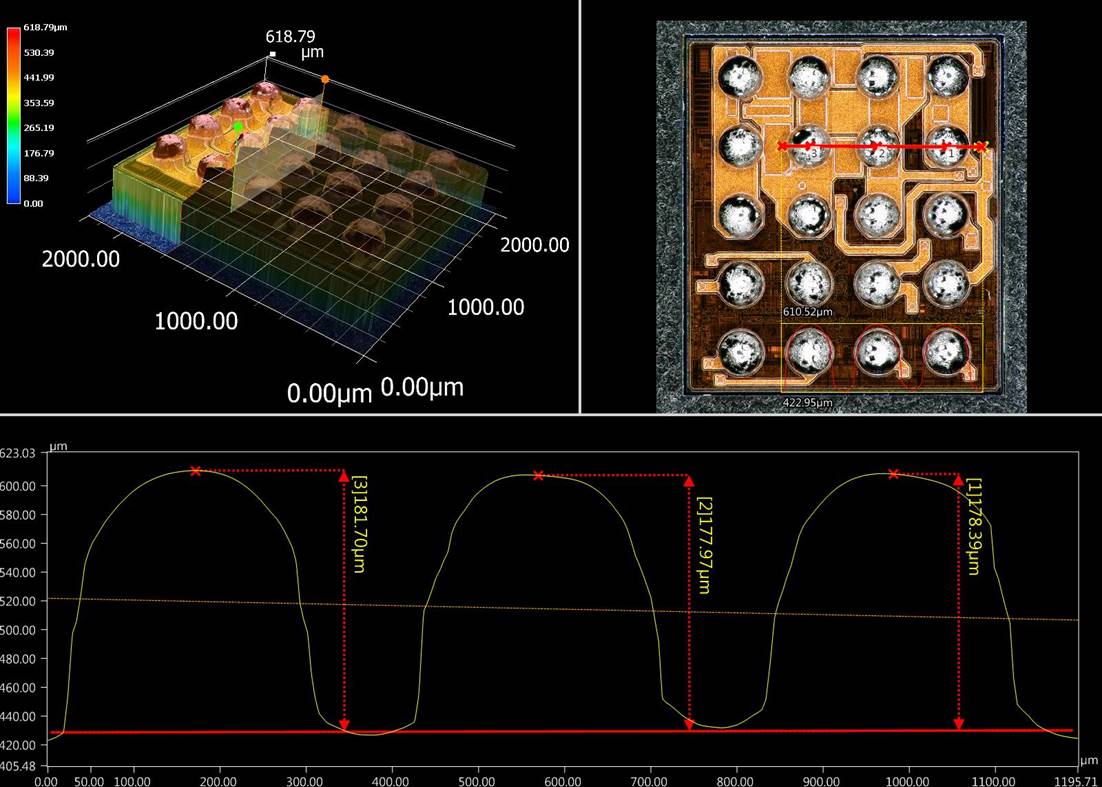

▍High-resolution 3D optical microscopy

Unlike ordinary optical microscopes, the VHX6000 OM can clearly present objects of different heights in a sample on one image, you can also observe the side of the sample at Tilt angle, connect the picture at high magnification, and measure the sample.

▍Equipment

Figure-1. VHX6000

.jpg)

▍Specifications

- ▪ 20X-50X Lens

- ▪ 100X-1000X Lens

- ▪ 1000X-5000X Lens

- ▪ Tilt 90 degree

▍Applications

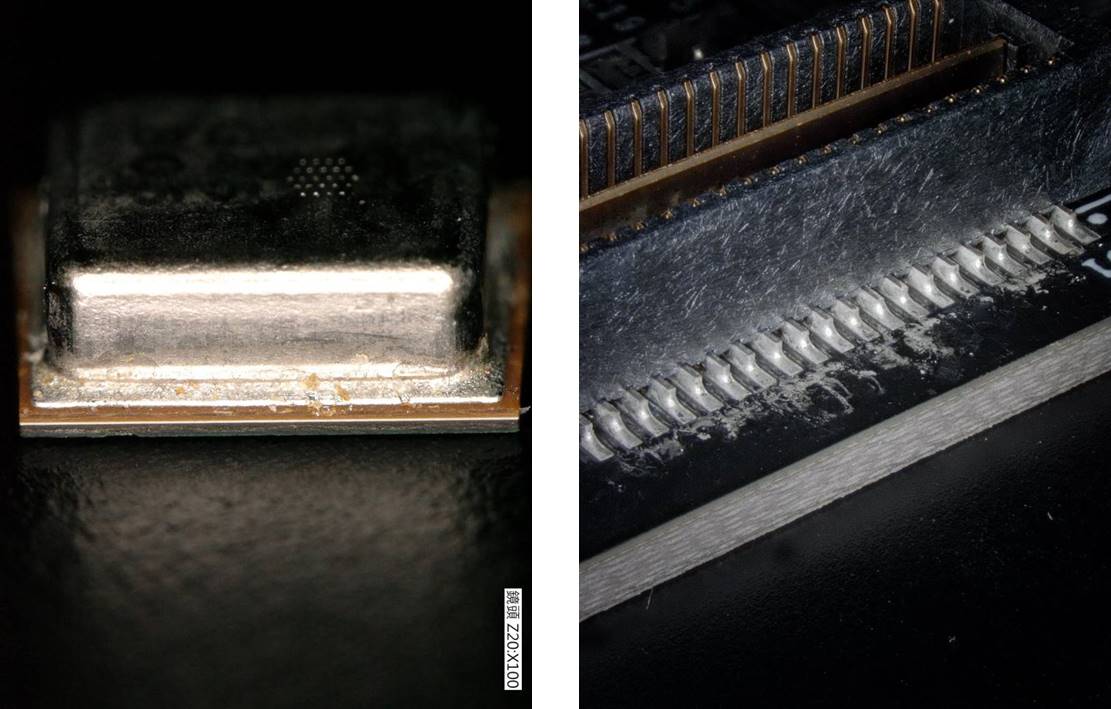

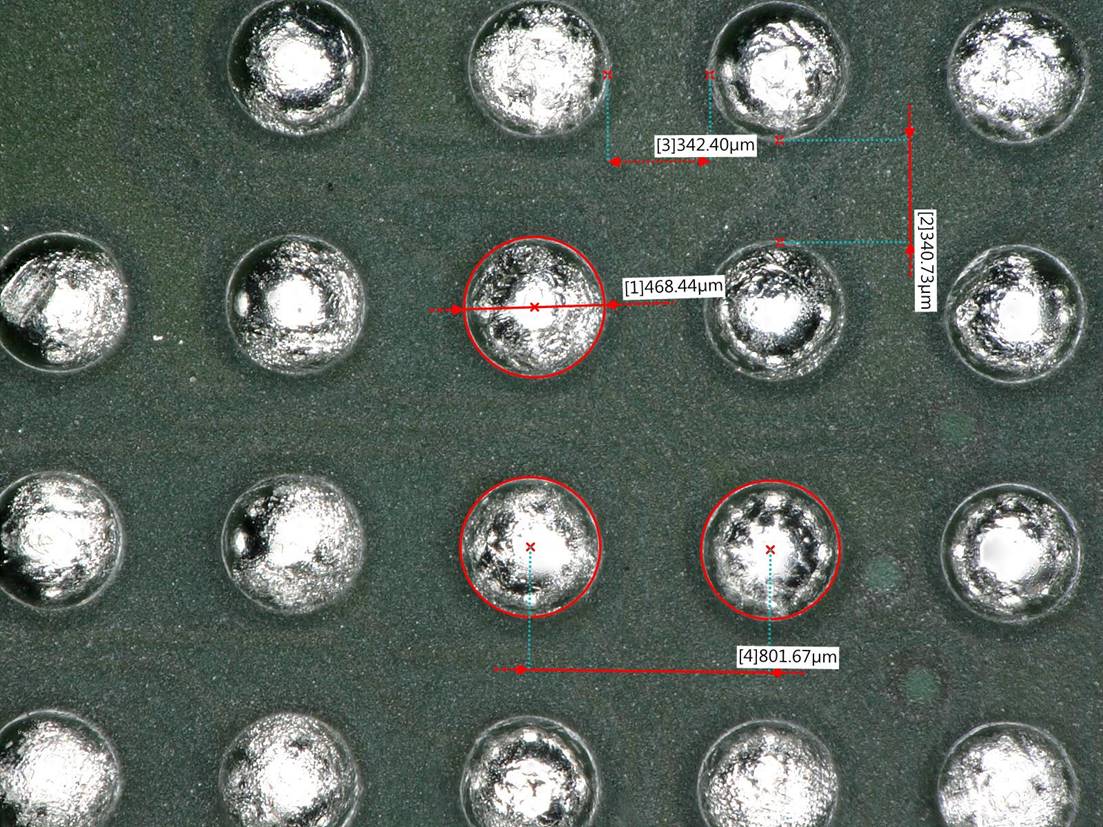

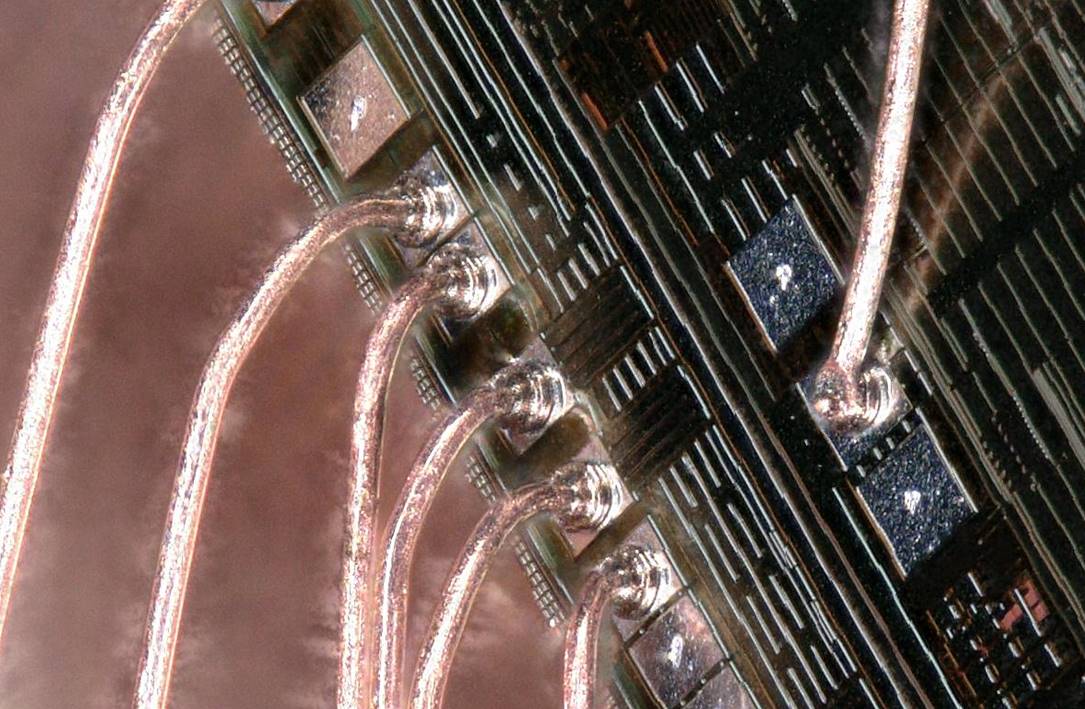

- ▪ Sample appearance inspection, such as surface damage, solder balls open, etc.

- ▪ Various sample measurements

- ▪ Observe the sample at an oblique angle

- ▪ Hand-held lens for large size samples

- ▪ Component observation on PCB board

▍Case Sharing

.jpg)

▍Eng. Contact Window

Mr. Wu ext.3677

E-mail: decap@msscorps.com